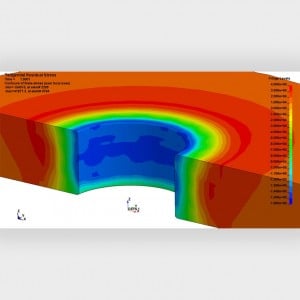

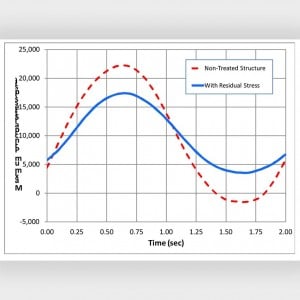

StressWave can analyze and optimize virtually all cold working processes. We combine a thorough understanding of non-linear behavior and response with many years of performing various cold working processes and installations. Ream, countersink and other common post processing machining operations can be simulated to examine their effect on residual stress and subsequent fatigue life. We have also created numerous special design applications of these processes to match unusual customer requirements for residual stress and strain fields.

Distortion analysis can be performed for components with one or more cold working locations. Changes in length, induced bending, and twist can be determined.

StressWave engineering creates products that are in use enhancing the safety, durability, and reparability of advanced structures. We use our expertise in inducing beneficial residual stress states and developing the hardware to implement the systems. Examples include:

- Expanded interference fit bushings

- Rivetless nutplates

- Post-weld treatments for various weld types

We can help with creation of new advanced systems for aerospace and other structures.